Die Struck Stamping

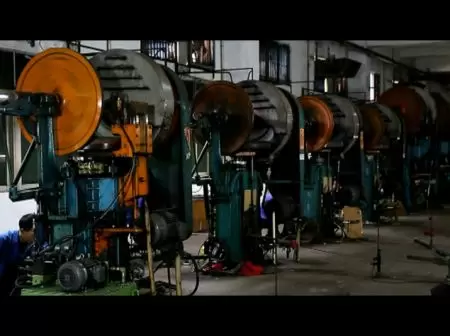

Die stamping machines and external shape cutting machines are the largest number machines we owned in factory. Most of stamping machines are controlled by foot and external shape cutting is handled by hands, plus jumbo-sized stamping machines, automatic stamping machines and hydraulic stamping machines, Jin Sheu surpasses our competitors not only in scale, in capacity also trumps in quality and delivery time.

- Video

-

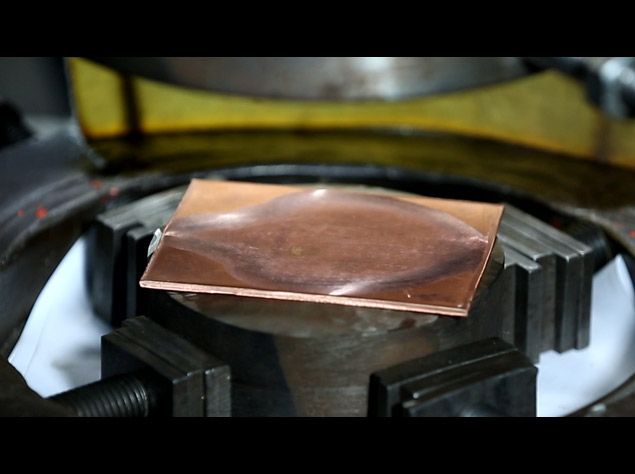

Jin Sheu Company runs over 50 stamping machines, mainly foot-controlled, some hand-controlled (for larger emblems), and a few automatic (for large orders). In the die striking process, motifs are created by stamping, with the metal size matching the mold size for high-pressure durability. Die striking is the prevalent method for crafting custom lapel pins, entailing mold engraving and motif transfer through stamping.

The majority of the stamping machines are foot-controlled, with some operated manually (for large-sized emblems), and a few automatic (for large quantity orders).

Jin Sheu owns the largest jumbo-sized stamping machines in the emblem industry, ideal for emblems over 3 inches. Single-sided emblems can reach a maximum diameter of 140mm, while double-sided emblems are limited to 90mm. As a self-reliant operation, we manage the engraving of large molds, external shape cut dies, and in-house die-struck stamping. Complete control over all procedures within our own factory ensures unparalleled quality compared to subcontractors handling individual processes.

The video presents Jin Sheu's external shape-cutting machines, essential for die-struck lapel pins. Mold engraving, die stamping, and external shape cutting are the key procedures. Whether emblems are printed, photo-etched, or die-struck, external shape cutting is necessary for the desired form. Items made through die casting, spin casting, and lost wax casting, where shapes form simultaneously with logo completion, don't need separate shape cutting; all other production methods require it for precision.

In our manufacturing, Jin Sheu's precision goes beyond shape cutting. After mold engraving and die stamping, attention to detail ensures high-quality die-struck lapel pins, regardless of the method—printed, photo-etched, or die-struck. External shape-cutting machines ensure the desired form.

The video illustrates the process of inner hole cutout.

- Gallery