Coloring Options for Lapel Pins, Coins, Medals, and More

In this department, we offer a variety of coloring options, including hard enamel, imitation hard enamel, and soft enamel. While many factories still rely on manual color filling, Jin Sheu has taken a different approach by investing in over 20 automatic soft enamel coloring machines. Additionally, we have recently started using UV printing techniques on our lapel pins, challenge coins, sports medals, and other products. At Jin Sheu, we are always eager to embrace new technology. We believe that by staying at the forefront of innovation, we can better serve our customers and enhance our own capabilities.

- Video

With Jin Sheu Company's skilled colorists, we tailor a wide range of colors to meet global demands, crafting diverse metal products, be it soft enamel, imitation hard enamel, or printed badges. This meticulous process guarantees accurate Pantone colors, complemented by 15 pristine enamel colors forming the basis for thousands of PMS shades.

Jin Sheu Company is a standout global manufacturer still crafting Cloisonné metal gifts, known for preserving colors unchanged for a century. Despite industry challenges, we maintain a sentimental connection and continue production for specific clients. Cloisonné's exceptional durability, unique glaze luster, unfading colors, and chip-free details make it the enduring choice for significant awards and military emblems.

Imitation hard enamel is increasingly preferred for custom metal gifts due to its likeness, cost-effectiveness, quick delivery, and diverse color range, gradually replacing some hard enamel pins. Jin Sheu Company highly recommends it for its favorable cost-performance ratio and color options. Customers consistently praise the enhanced brightness, shine, and smoothness of our imitation hard enamel pins. Production procedures closely mimic hard enamel, varying in color options, drying process, and grinding machines. Unlike hard enamel colors imported in powder form, liquid-form imitation hard enamel offers flexibility and is domestically sourced. The drying process involves an 80℃ oven for imitation hard enamel, while hard enamel colors undergo an 800℃ burn. Both hard enamel and imitation hard enamel share the same grinding machine but use different wheel sets. Hard enamel wheels are coarser, while imitation hard enamel wheels are finer.

Besides automated production, Jin Sheu assesses orders and, for smaller quantities, employs manual production for crafting Imitation Hard Enamel, showcasing color filling through small pinholes in visual effects.

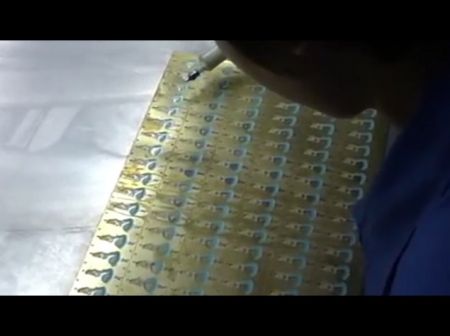

The video showcases Photo Etch Soft Enamel Coloring, a technique different from die-struck, printing, or spin casting. Logos or motifs are acid-etched, creating shallower recessed areas compared to die-struck emblems. Most photo-etched emblems, with a thickness of 0.7mm to 0.8mm, maintain consistent thickness for large-sized medals. Prior to external shape cutting, all procedures, including photo etching and coloring, utilize a large plate instead of individual pieces. Shape cutting precedes electroplating.

Jin Sheu owns several soft enamel automatic coloring dispensing machines that allow a worker to operate 2-3 machines simultaneously. Auto-coloring machines are widely used in making lapel pins, challenge coins, ball markers, dog tags, etc. This type of automatic color dispensing machine can detect and track the logo's angle and position, dispensing colors precisely and quickly. It is suitable for orders with a simple design and large colored areas.

Through video, Jin Sheu recommends our soft enamel automatic coloring dispensing machine, a unique type requiring precise lapel pin arrangement before coloring. Due to preparation time, this method is suitable for orders over 1000 pcs. After the initial job, repeat orders are expedited with ready programming. With 20 auto-coloring machines and numerous coloring laborers, Jin Sheu leads in custom-made lapel pins and emblems.

Jin Sheu evaluates smaller quantities and utilizes production for crafting soft enamel coloring. The soft enamel colors are in a liquid stage, and the filled colors are usually below the metal borders.

With UV printing, the only limit is your imagination. Let your creativity soar and watch as your lapel pin designs, award medals, or police badges come to life with vivid colors and impeccable detail. Join us on this exciting journey of innovation and discovery, where the possibilities are endless, and the results are truly remarkable.

- Gallery